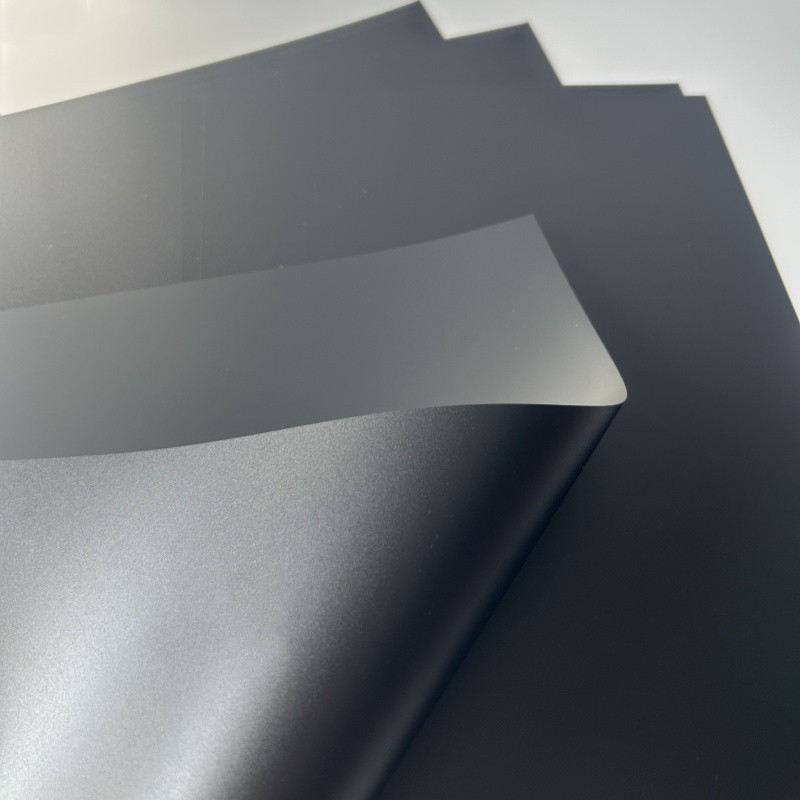

Products Description

Black FR PC Film is a black item,flame-retardant polycarbonate film with a varietyof different surface textures and a UL94 V-0 or VTM-0 listing. This film with formability, excellent mechanical properties,good dimensional stability in high temperatures and a high flammability rating.The texuture can be velvet/matte,fine velvet/matte or customized. The general size and thickness are as follows:

| Item | Color | Texture | Thickness(mm) | W*L | Kg/Roll | Qty/pallet |

| SYF832B | Black | Fine velvet/matte | 0.05 | 930mm*1450m | 80kg | 6 rolls |

| 0.075 | 930mm*1000m | 80kg | 6 rolls | |||

| 0.1 | 930mm*750m | 80kg | 6 rolls | |||

| 0.125 | 930mm*640m | 89.3kg | 6 rolls | |||

| 0.175 | 930mm*457m | 89.3kg | 6 rolls | |||

| 0.2 | 930mm*400m | 89.3kg | 6 rolls | |||

| SYF825B | Black | Velvet/matte | 0.25 | 930mm*320m | 89.3kg | 6 rolls |

| 0.375 | 930mm*213m | 89.3kg | 6 rolls | |||

| 0.43 | 930mm*185m | 89.3kg | 6 rolls | |||

| 0.5 | 930mm*160m | 89.3kg | 6 rolls | |||

| 0.76 | 930mm*106m | 89.3kg | 6 rolls |

Application

Black FR PC Films are used in heat insulation film, hot air separator,electrical Insulation,EMI Shield. Such as printed circuit board insulation,backlit aircraft in-flight panels and displays power supply insulation, disc drive insulation,bus-bar insulation,TV/monitor insulation,business equipment insulation and has insulation and EMI/RFI shielding when laminated with metal foil.

Properties of insulation polycarbonate film

|

TYPICAL PROPERTY VALUES |

||||

|

PROPERTY |

Test Method |

Units |

Value |

|

|

PHYSICAL |

||||

|

Specific Gravity |

ASTM D792 |

g/cm3 |

1.2 |

|

|

Water Absorption Equilibrium,24 Hrs |

ASTM D570 |

% |

0.35 |

|

|

MECHANICAL |

||||

|

Tensile Strength |

ASTM D882 |

psi |

8,800 |

|

|

ISO R1184-1987 |

Mpa |

60 |

||

|

Elongation Ultimate |

ASTM D882 |

% |

>90 |

|

|

Impact Strength @ 10mils |

JIS-k6745 |

In-ibs |

120 |

|

|

Tear Strength Propagation |

ASTM D1922 |

g/mil |

>30 |

|

|

HEAT RESISTANCE |

||||

|

Vicat Softening Temperature |

ASTM D1525 |

℃ |

135 |

|

|

Heat Shrinkage Rate |

ASTM D1204 |

% |

<0.2 |

|

|

ELECTRICAL |

||||

|

Dielectric Strength(@ 10 mils) |

ASTM D149 |

V/mil |

1,700 |

|

|

Volume Resistivity @25℃,50%RH |

ASTM D257 |

Ohm-cm |

1016 |

|

|

Surface Resistivity @25℃,50%RH |

ASTM D257 |

Ohm-cm |

1015 |

|

|

FLAMMABILITY |

||||

|

UL Flammability |

UL BULLETIN 94 |

|||

|

TY95 (0.05-0.2)mm |

UL94 |

VTM-0 |

||

|

TY71 (0.25/0.38/0.43/0.5/0.76/1.0)mm |

UL94 |

V0 |

||

|

OXYGEN INDEX @ 10MILS |

ASTM D2863 |

% |

32 |

|

|

Traits |

Unit |

Ultimate value |

||

|

Thickness tolerance |

% |

﹤0.5mm±5% |

||

|

≥0.5mm±3% |

||||

|

Storage temperature |

℃ |

Temperature 20±10℃ moisture 50%±10℃ |

||

|

The validity time of storage |

No change in 9 months |

|||

FAQ

Q1:Can we get the free samples of Black FR PC Film?

A:Yes, the samples are free, you only pay the shipping cost or give your courier account to send the samples.

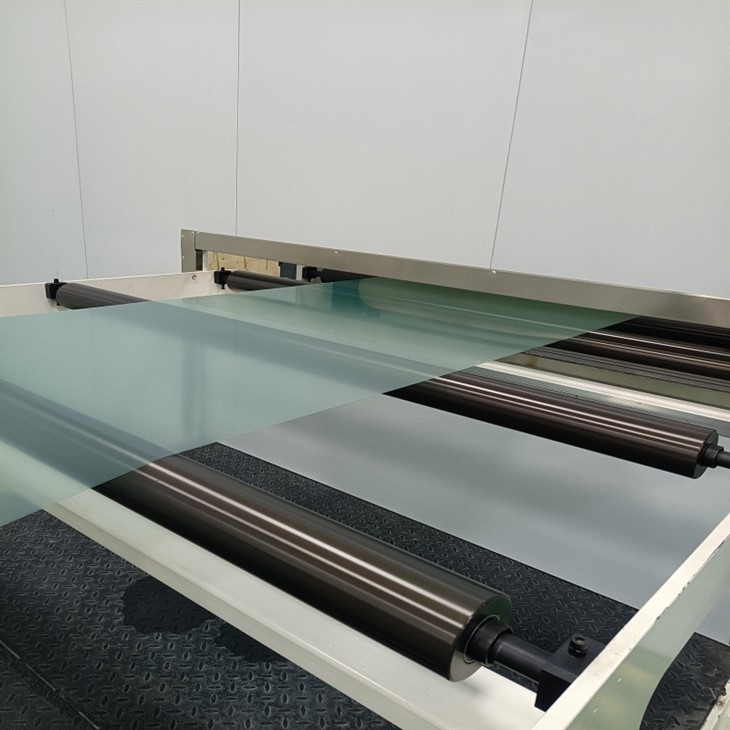

Q2:Are you a manufacturer with factory or a trading company?

A:We are a manufacturer of plastic film, the factory is located in Suqian city,Jiangsu Province,China.

Hot Tags: black fr pc film, China black fr pc film manufacturers, suppliers, factory, PETG White Core Sheet, ID Card Polycarbonate Film, High Gloss PETG Film, Black Polycarbonate Film, Black PC Film, 0 5mm PC Sheet