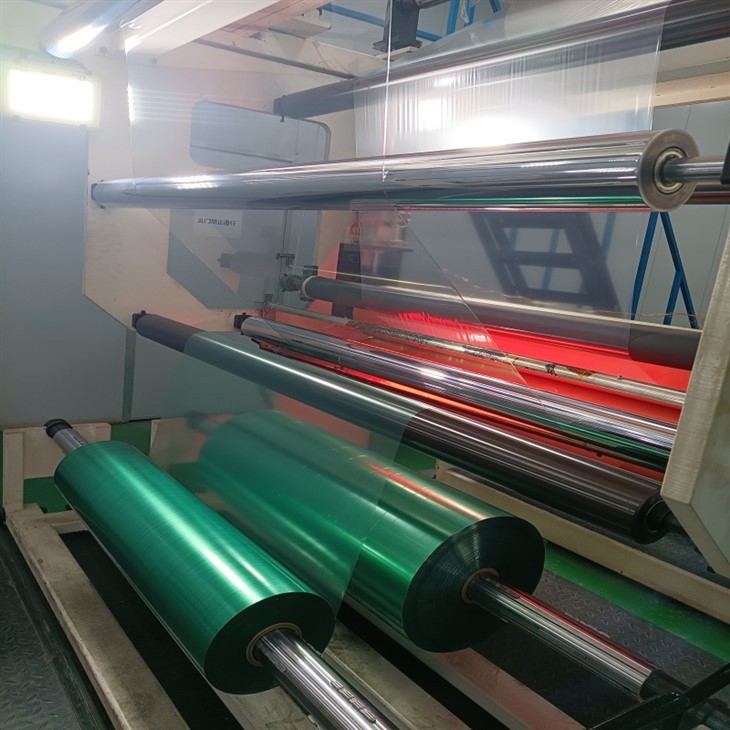

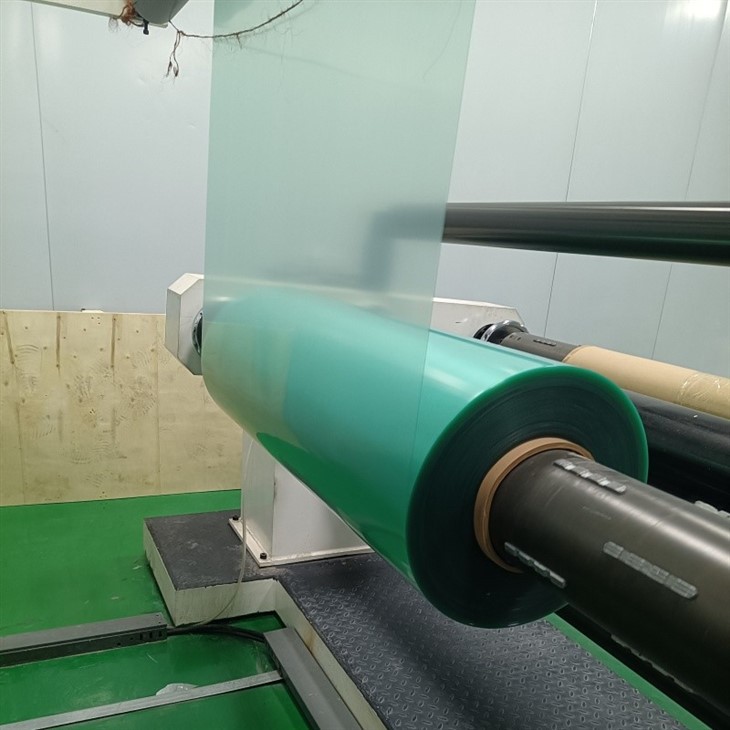

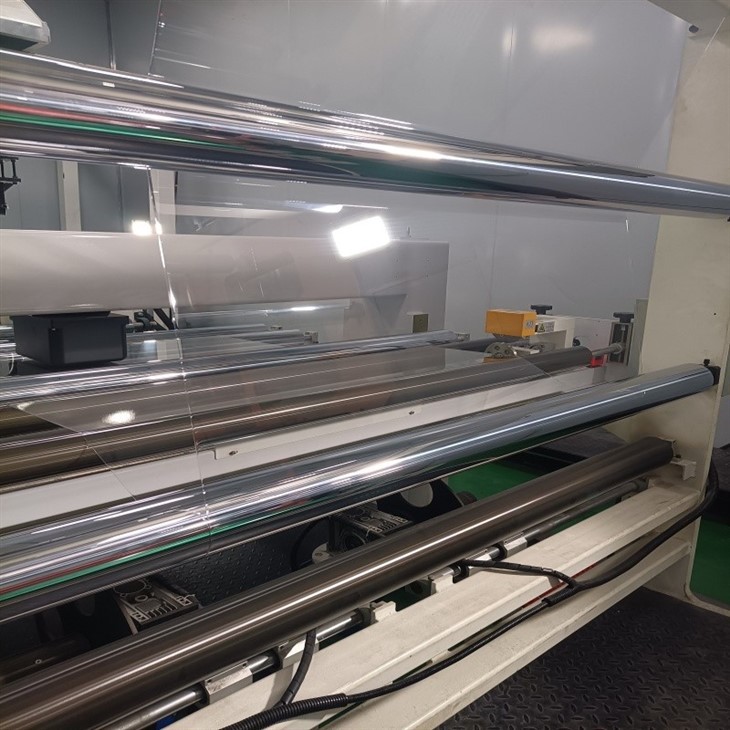

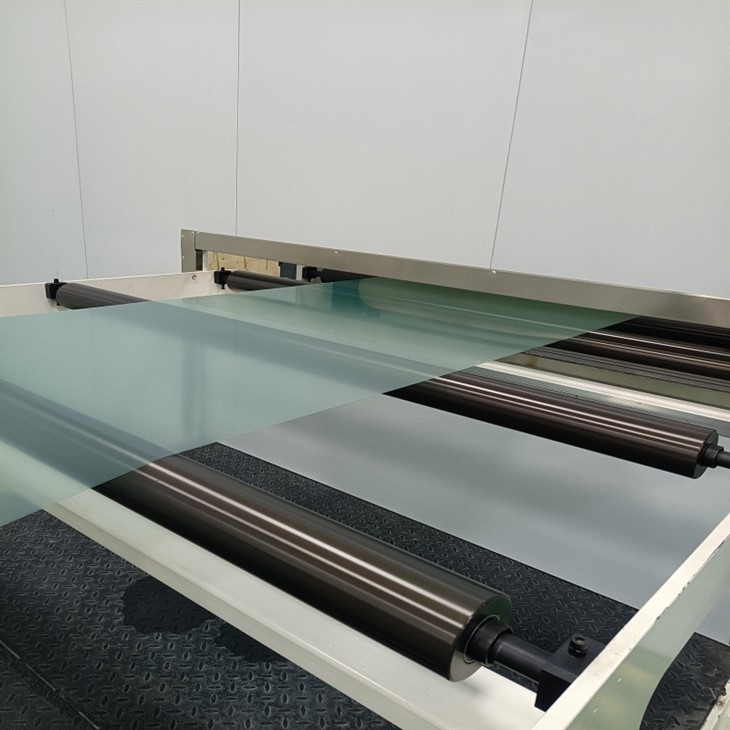

Products Description

Because of its excellent physical and chemical properties, polished polycarbonate film has a wide range of applications in many fields, the following details of its application in membrane switches, control panels, nameplate, protective masks, instrument panels and wide-angle mirrors.

Membrane switch:Clear polycarbonate films play an important role in the manufacture of film switches because of their excellent insulation, high transparency and good mechanical properties. It can be used as the substrate of the switch, which is printed with conductive lines and contacts, and then covered with a layer of insulation to form a complete film switch. The switch is widely used in home appliances, communication equipment, medical equipment and other fields, with thin, beautiful, durable and other characteristics.

Control pannel:In the production of control panels, clear polycarbonate films also play an essential role. It can be used as the substrate of the panel, which is printed with various buttons, indicators and other patterns, and then processed by special processes to make it have touch function. The control panel is waterproof, dust-proof and wear-resistant, and is widely used in industrial control, automotive electronics and other fields.

Key Characteristics

| Properties | Test Method | Unit | Value | |

| Specific Gravity | ASTM D792 | g/cm3 | 1.2 | |

| Water Absorption Equilibrium,24 Hrs | ASTM D570 | % | 0.35 | |

| Light Transmission | ASTM D1003 | % | ≥89 | |

| MECHANICAL | ||||

| Tensile Strength | ASTM D882 | psi | 7,500 | |

| ISO R1184-1987 | Mpa | 50 | ||

| Elongation ultimate | ASTM D882 | % | >90 | |

| Impact Strength @ 10mils | JIS-k6745 | In -Ibs | 60 | |

| Tear Strength Propagation | ASTM D1922 | g/mil | >30 | |

| THERMAL | ||||

| Vicat Softening Temperature | ASTM D1525 | ℃ | 135 | |

| Thermal shrinkage rate | ASTM D1204 | % | 0.8 | |

Applications

Instrument panel

polished polycarbonate film is also widely used in the manufacture of instrument panels. It can be applied as the panel material of the instrument panel, which is printed with various scales, indicators and other patterns, and then processed by special processes to make it have wear resistance, anti-aging and other properties. The instrument panel with the characteristics of high clarity, good stability and long service life, and is widely used in vehicles such as automobiles, motorcycles, ships and all kinds of machinery and equipment.

Protective mask

The protective mask is made of transparent polycarbonate film, with the characteristics of light weight, high transparency and impact resistance. It can effectively protect the wearer's face from splashing, harmful gases and so on. At the same time, its good air permeability and anti-fog performance also ensure the comfort of wearing and clear vision. This kind of protective mask is widely used in industrial, medical, fire and other fields.

Advantages

What are the advantages of polished polycarbonate film compared with other plastic films?

Transparent PC films have several advantages over other plastic films. First, it has high transparency and excellent optical properties. Secondly, it has good mechanical properties,impact resistance and high temperature resistance and UV resistance. These advantages make transparent PC films as the prior choice in many applications.

Hot Tags: polished polycarbonate film, China polished polycarbonate film manufacturers, suppliers, factory, Identity Card Polycarbonate Film, PETG Card Material, Insulation Polycarbonate Film, 21s, PETG Card Core, Polycarbonate Film for Driving License