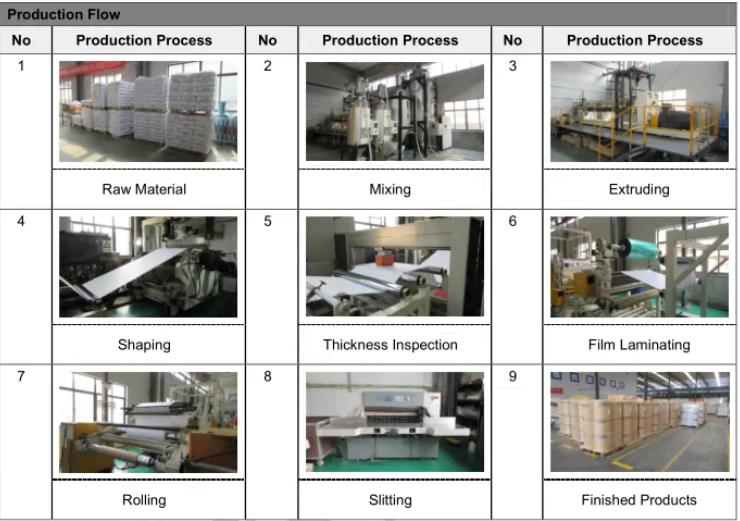

How to produce polycarbonate sheet and film?

The production involves several intricate processes to ensure the material's desired properties and quality. Here is an overview of the typical production processes for polycarbonate film:

1. Raw Material Preparation:

The process begins with the preparation of high-quality polycarbonate resin pellets, which serve as the raw material for film production. These pellets are carefully selected for purity and consistency.

2. Extrusion:

The polycarbonate resin pellets are melted using heat in an extruder.

The molten polycarbonate is then extruded through a flat die, forming a continuous sheet of film.

3. Cooling and Solidification:

The extruded film passes through a cooling process to solidify the molten polycarbonate.

Controlled cooling is crucial to achieve the desired thickness and surface characteristics.

4. Orientation (Optional):

In some cases, the film may undergo orientation to enhance its mechanical properties. This can involve stretching the film in one or both directions to align the polymer chains.

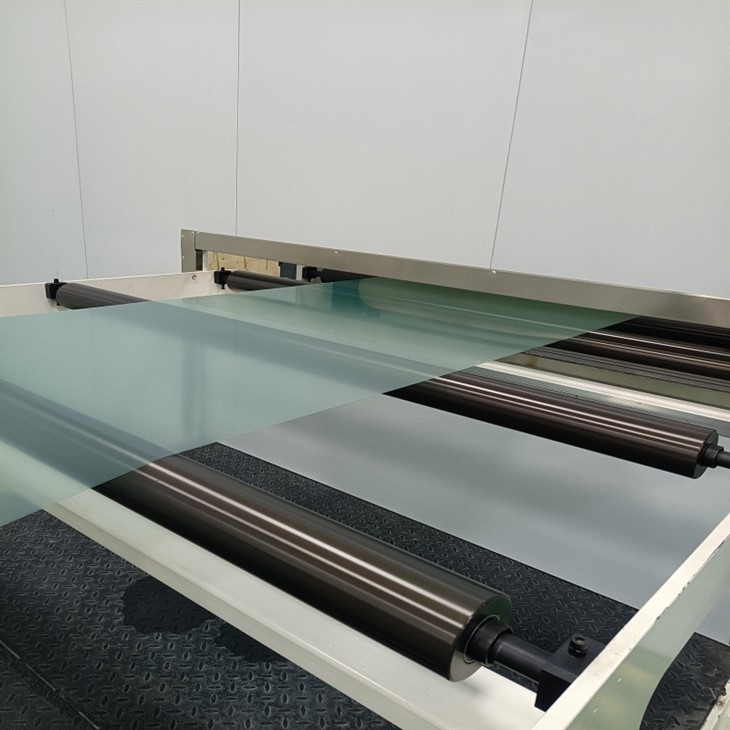

5. Calendering (Optional):

Calendering is a process that involves passing the film through a series of rollers to achieve precise thickness control and surface smoothness.

6. Rolling and Annealing:

The film is subjected to annealing, a controlled heating and cooling process, to relieve internal stresses and improve overall film properties, including dimensional stability.

7. Slitting:

The wide film is then slit into narrower rolls according to the desired width specifications. This step facilitates handling and packaging.

8. Quality Control:

Throughout the entire production process, quality control measures are implemented. These may include checks for thickness uniformity, optical clarity, surface defects, and adherence to specifications.

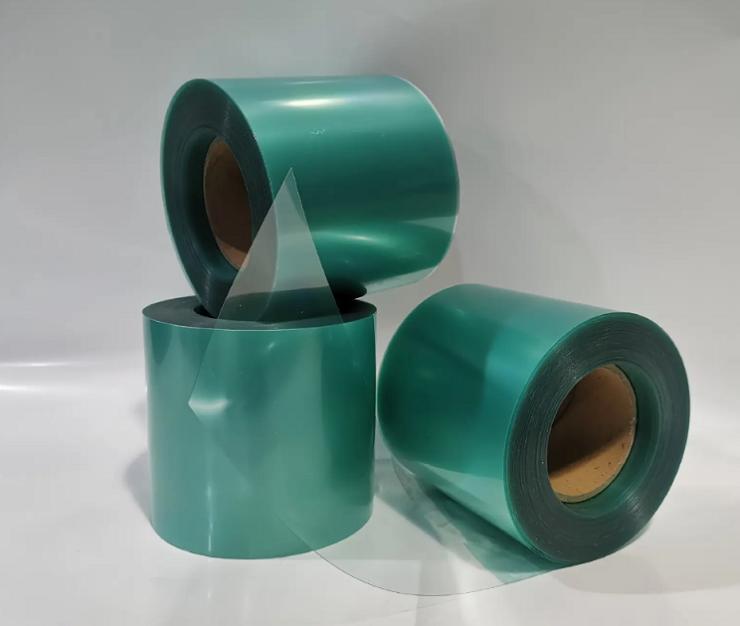

9. Packaging:

The final polycarbonate film rolls are carefully packaged to protect them during transportation and storage.

10. Shipping:

The finished rolls are then shipped to customers for use in various applications

Specification

|

Item |

Color |

Texture |

Thickness(micron) |

W*L |

Kg/Roll |

Qty/pallet |

|

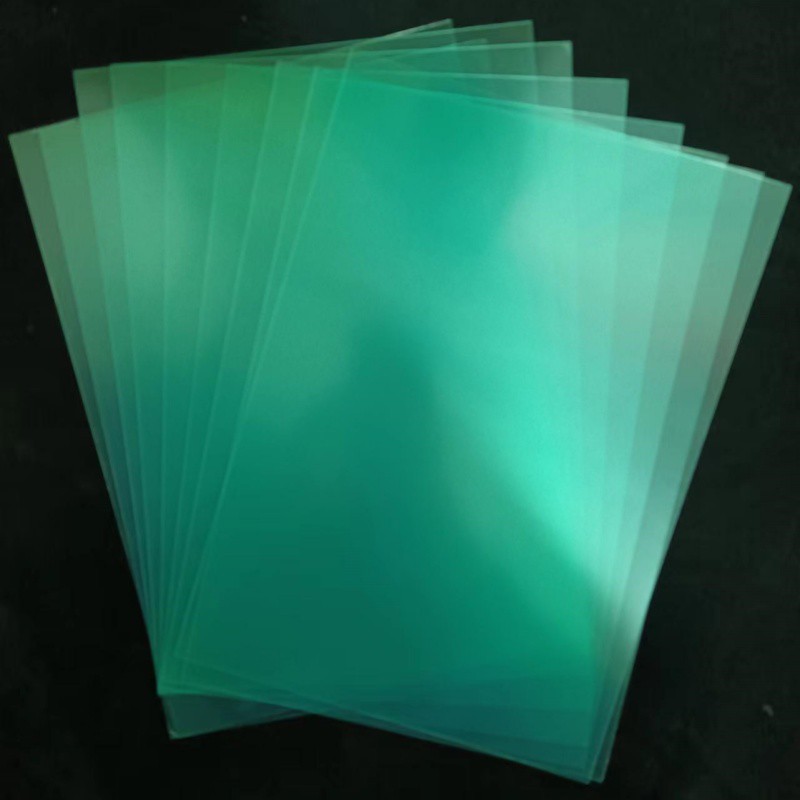

SY811 (ROLL) |

Transparent |

gloss/gloss |

100 |

930mm*500m |

55.8kg |

6 rolls |

|

125 |

930mm*400m |

55.8kg |

6 rolls |

|||

|

175 |

930mm*350m |

68.4kg |

6 rolls |

|||

|

250 |

930mm*300m |

83.7kg |

6 rolls |

|||

|

300 |

930mm*250m |

83.7kg |

6 rolls |

|||

|

375 |

930mm*200m |

83.7kg |

6 rolls |

|||

|

500 |

930mm*150m |

83.7kg |

6 rolls |

|

Item |

Color |

Texture |

Thickness(micron) |

W*L |

Kg/Roll |

Qty/pallet |

|

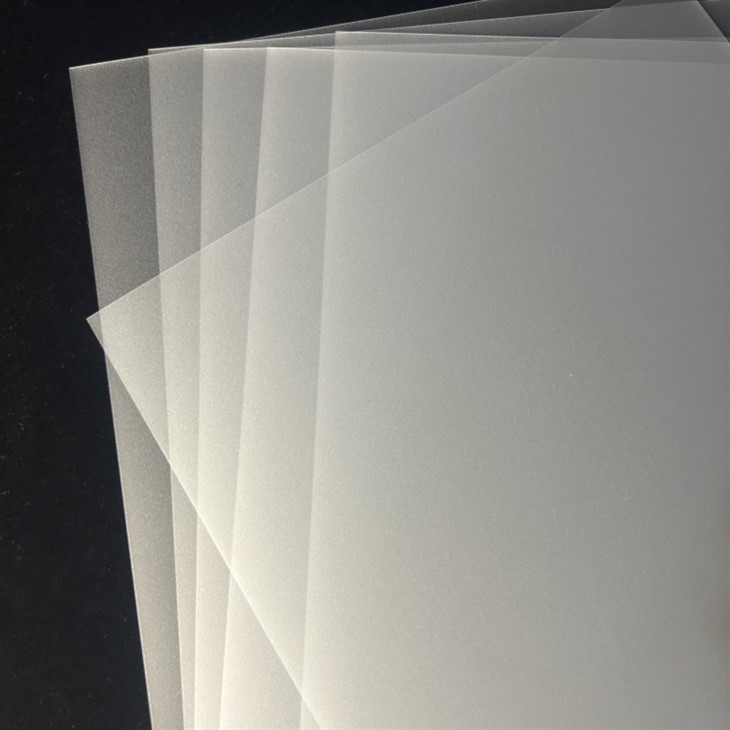

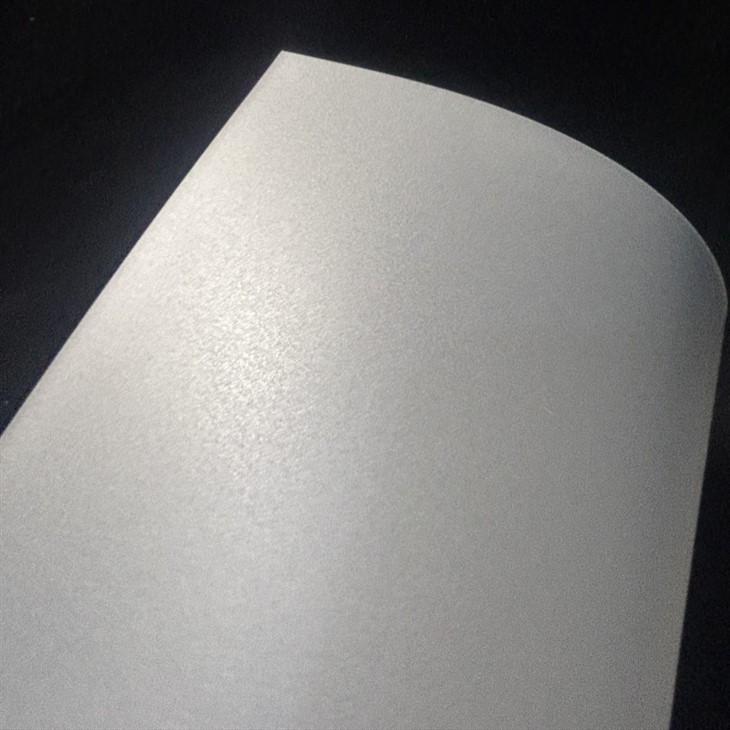

SY835 (ROLL) |

Natural |

Velvet/matte |

125 |

930mm*640m |

89.3kg |

6 rolls |

|

175 |

930mm*457m |

89.3kg |

6 rolls |

|||

|

250 |

930mm*320m |

89.3kg |

6 rolls |

|||

|

375 |

930mm*213m |

89.3kg |

6 rolls |

|||

|

500 |

930mm*160m |

89.3kg |

6 rolls |

|||

|

760 |

930mm*106m |

89.3kg |

6 rolls |

FAQ

1. Q: Can I become Zhenzhen's agent to distribute the pc films?

A: Yes, we are glad that you can be our agent, helping us to distribute our PC films in your local market.

2. Q: How to support us if we are the agent of Zhenzhen?

A: Special Prices, technical support, production etc. Welcome to consult our sales team.

Hot Tags: polycarbonate sheet and film, China polycarbonate sheet and film manufacturers, suppliers, factory, Thin Polycarbonate Film, FR PC Film, Clear PC Film, Flame Retardant Polycarbonate Film, Transparent Polycarbonate Film, Velvet Polycarbonate Film