PVC Period Is Now Rising.STOCK: Nothing To Do With Me

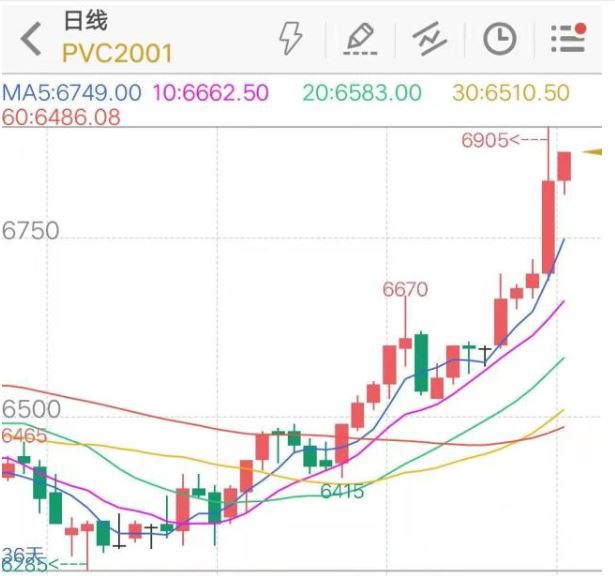

The current price of PVC fluctuated and stabilized in late October. After entering November, it went out of the unilateral upward trend, with a cumulative increase of more than 10% from the low point. The market has reached new highs one after another in the confusion of most participants, and there seems to be no sign of stopping at present.

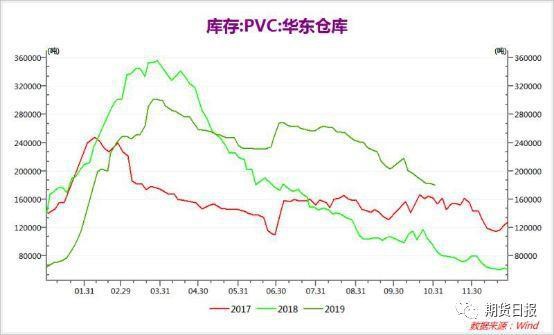

Some researchers intend to find a breakthrough in market research from the perspective of inventory. It is true that low inventory is often the catalyst for the sharp rise in the price of chemicals, but this time it is different. In terms of absolute volume, PVC inventory in East China is at a high level in the same period of nearly three years, and there is no sign of accelerating downward trend in terms of change trend. It is difficult to get a reasonable explanation for the price rise in the past month from the perspective of current inventory, so it is impossible to make a relatively accurate inference from the inventory change to the later market.

There must be fundamental industrial logic changes corresponding to the big market, and the fundamental industrial logic changes will also create the big market far beyond the general expectation of the market. We believe that there are three factors supporting the price rise:

First, the previous stage of price rise is a correction to the pessimistic expectation of the previous market demand.

Since this year, the market's pessimistic expectation of real estate has resulted in the collective wrong killing of building materials commodities. Data shows that real estate is still in the super long boom cycle starting in 2016. In October, the completed area of houses in a single month was 53.8985 million square meters, up 18.82% year on year. Before the completion of the house, there should be complete water supply and drainage pipes and plastic steel doors and windows, and there is a rigid demand for PVC materials. The return of the completed area to high growth means that the rigid demand of PVC for new commercial housing still keeps high growth. At the same time, livelihood projects and development projects involving hundreds of millions of people, namely, the transformation of old urban communities, have been carried out in an all-round way this year on the basis of the previous two years' pilot experience. The renovation of the old town community involves a large number of PVC application scenarios, such as the replacement of water supply and drainage pipes, the replacement of single-layer glass doors and windows of old-fashioned iron into insulated hollow glass plastic steel doors and windows, the replacement of floor leather, etc. Under the combined effect of new commercial housing and old residential area reconstruction, PVC demand remained at a relatively high level, so the rise of PVC was supported by demand.

Second, the current upward price is closely related to the centralized management of work safety in the hazardous chemicals industry.

According to the Ministry of emergency management on November 23, the work safety committee of the State Council printed and distributed the work plan for centralized rectification of national work safety on that day, and carried out three-month centralized rectification of work safety in key industries such as hazardous chemicals nationwide. PVC production enterprises belong to hazardous chemicals industry, especially PVC enterprises adopting carbide process, which are extremely dangerous due to extremely active chemical properties such as combustible gas generated by calcium carbide encountering water. In recent years, several serious safety production accidents have occurred in Hebei, Inner Mongolia Autonomous Region and other places. PVC production enterprises should be the key target of this centralized renovation. The centralized rectification work "sharpening the knives without mistaking the firewood cutter" is conducive to protecting the safety of people's lives and property, but it will affect the supply of PVC raw materials in the upstream from December to February. The current upward price of PVC is supported by the expectation of supply reduction.

Third, 2020 is the key time node of Minamata convention, and a large number of backward production capacity of calcium carbide method is facing great exit pressure.

On August 31, 2016, China became the thirtieth country to ratify the Minamata Convention on mercury. On August 16, 2017, the Minamata Convention on mercury was officially implemented. China's Mercury related fields mainly include PVC production by calcium carbide method, primary mercury ore, mercury light source, etc. The mercuric chloride content of high mercury catalyst used in carbide method is 10.5% - 12%, and the consumption of catalyst is about 1.2kg/t. The annual consumption of mercury in PVC industry accounts for 85% of the total consumption, which becomes the key constraint object of the Convention. The Convention provides for the elimination of mercury containing processes in the chlor alkali industry by 2025. According to the requirements of the Convention and the preliminary assessment, the Ministry of environmental protection has given the implementation schedule. It is required that by 2020, the mercury consumption per unit product of PVC monomer will be reduced by 50% compared with that in 2010. At present, the economy and product quality stability of PVC low mercury catalyst process and mercury free catalyst process produced by calcium carbide process are still lower than those of high mercury catalyst process. Enterprises tend to maintain the original process route from their own interests, and the overall technology update of the industry is relatively slow. Under the pressure of continuous environmental protection, the carbide process unit, which accounts for a large share of PVC production capacity in China, will face a large-scale exit pressure. It is the general trend for the mainstream process of the industry to shift from carbide process to ethylene process, and the production cost center will rise accordingly, so as to support the price of PVC.

To sum up, the price change of PVC reflects the current supply and demand expectations and industrial changes, with its inherent rationality, and the price will continue to rise steadily in the later period. It is suggested that the downstream processing enterprises should arrange strategic buying hedging positions for contracts lower than May and September. (author unit: China International Futures)