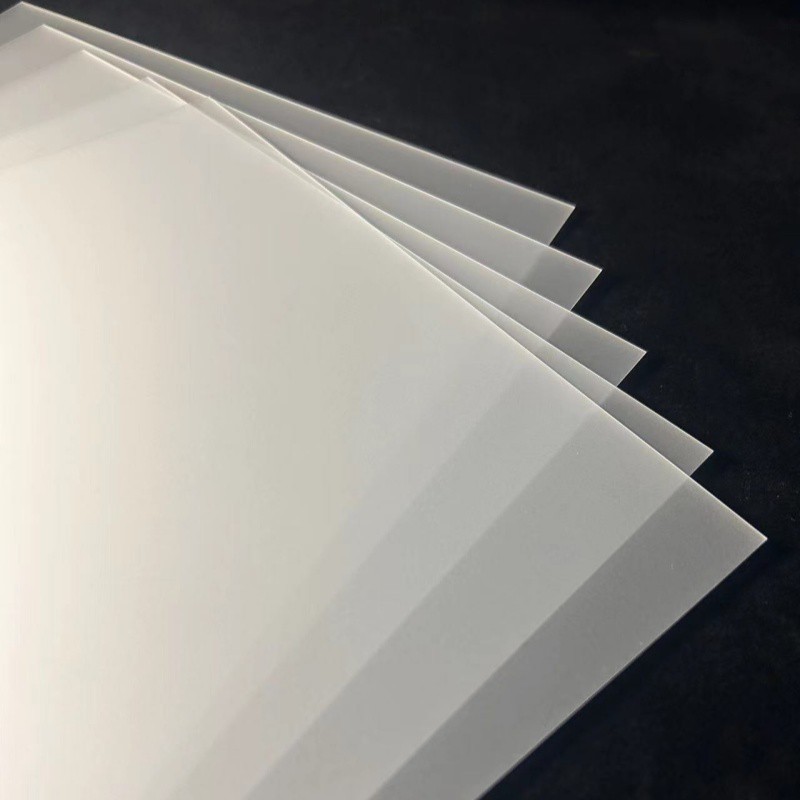

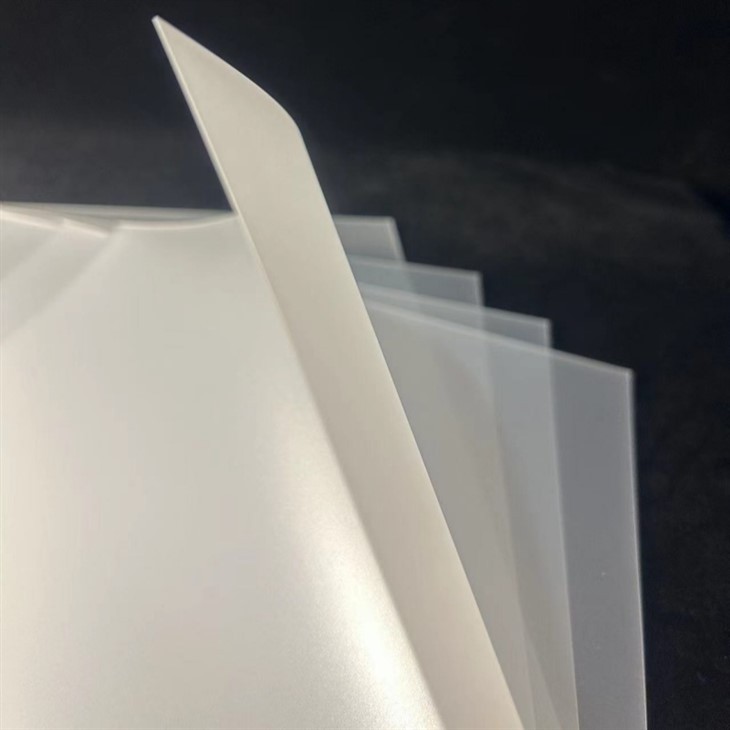

Products Description

The frosted series polycarbonate(PC) film exhibit exceptional chemical resistance, superior formability, and excellent printability. The frosted polycarbonate film makes it highly versatile for applications in various fields, including instrument panels, membrane switches, panels, labels, and more.

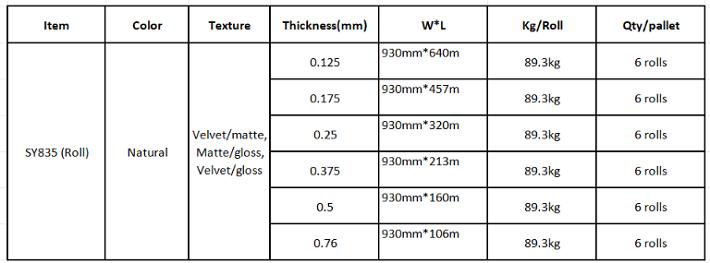

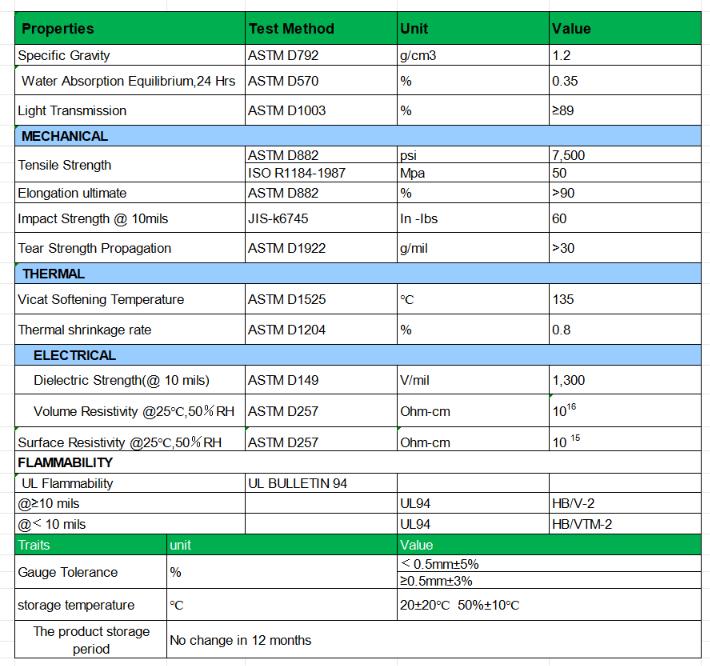

Typical Properties Values

About us

Zhenzhen is dedicated to the research and development, as well as the manufacturing of functional films and card base materials. Our primary product offerings include Polycarbonate (PC) and Polyethylene Terephthalate Glycol (PETG) films and sheets. These materials find extensive applications in various industries such as new energy batteries, electronics, communication displays, consumer protection, smart cards, security printing (ID cards, passports, driving licenses), and furniture decoration.

With a comprehensive research and development team, Zhenzhen addresses customer needs through independent research and innovation. Currently, we hold ISO certification and the MEDICAL DEVICES QUALITY MANAGEMENT SYSTEM CERTIFICATE issued by BSIC. Our products have successfully passed SGS tests, complying with the environmental protection standards of ROHS and REACH.

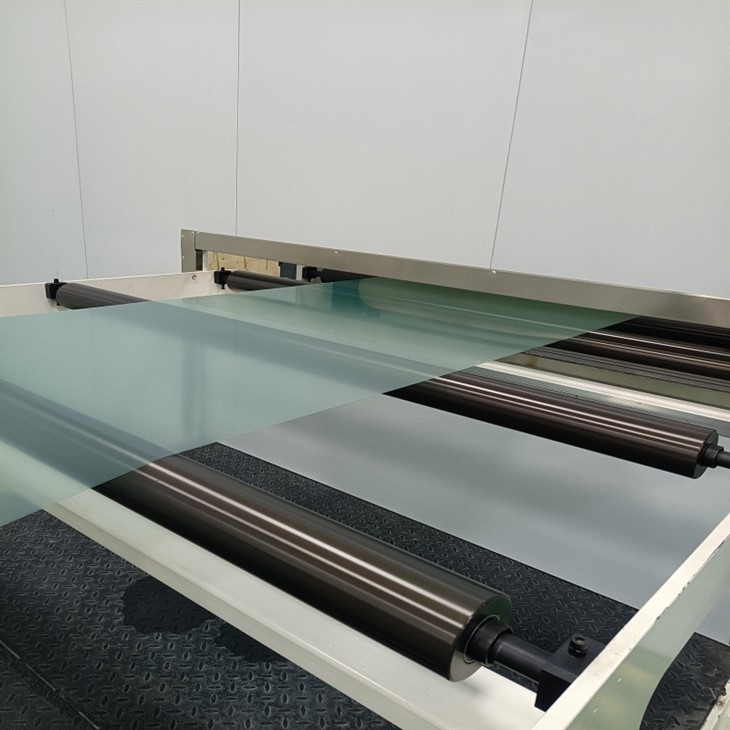

Our production lines

The production of frosted polycarbonate film involves several key mechanical equipment and machinery. Some of the essential equipment required includes:

Extrusion Line: Used for the extrusion of molten polycarbonate material to form a continuous film.

Casting process Machine: Employed to cast the extruded film to achieve the desired thickness and smoothness.

Rolling Mills: Utilized for further refining and stretching the film to enhance its mechanical properties and thickness uniformity.

Cooling and Quenching System: Necessary to cool and solidify the film after extrusion and calendering processes.

Cutting and Slitting Machines: Used for cutting the film into desired dimensions and slitting it into rolls as per specific requirements.

Surface Treatment Equipment: Applied for adding surface textures such as matte, velvet, or suede finishes to the polycarbonate film.

Printing Equipment: If required, printing machinery is used for adding designs, patterns, or information onto the film surface.

Quality Control Systems: Various monitoring and testing equipment to ensure the film meets specified standards for thickness, strength, and other properties.

Winding Machines: Used for winding the finished polycarbonate film onto rolls for storage, transport, or further processing.

Hot Tags: frosted polycarbonate film, China frosted polycarbonate film manufacturers, suppliers, factory, Car Battery FR PC Film, Polycarbonate Film Roll, FR PC Film, Polycarbonate Sheet and Film, Velvet Polycarbonate Film, Glossy Polycarbonate Film